2020

LASS carries out research in three areas: carbon based materials, computational material science and x-ray related methods. In the last year we have reached significant results in all of these fields.

Carbon based systems.

One of the unique applications of carbon nanotubes is their use as nanocontainers for various encapsulated species. We could succesfully encapsulate sexithiophene molecules in single-walled carbon nanotubes using two different methods: sublimation filling at 400 °C and nanoextraction from supercritical carbon dioxide at 50 °C. We observed thermally induced polymerization during sublimation filling, which increased the electronic conjugation length of the chains inside the nanotubes. Although the conjugation length in the thiophene chain is increasing upon heating, no Raman signatures of graphene nanoribbons are observed [1]. These results complement our earlier studies, in which metal nanoclusters were encapsulated in the nanotubes.

An other type of the carbon based systems are fullerene cocrystals. Based on the analysis of the supramolecular interactions in several high-symmetry fullerene cocrystals, a consistent model has been worked out to predict the formation and stability of similar high symmetry molecular crystals [2]. In one of the cocrystal built from metallofullerenes and highly energetic cubanes, an anomalous, irreversible, pressure-driven lattice expansion has been detected by applying high pressure. Based on detailed theoretical and experimental study of this system, a new strategy was suggested for the creation of composite materials with similar negative volume compressibilities with exciting potential applications in various fields [3].

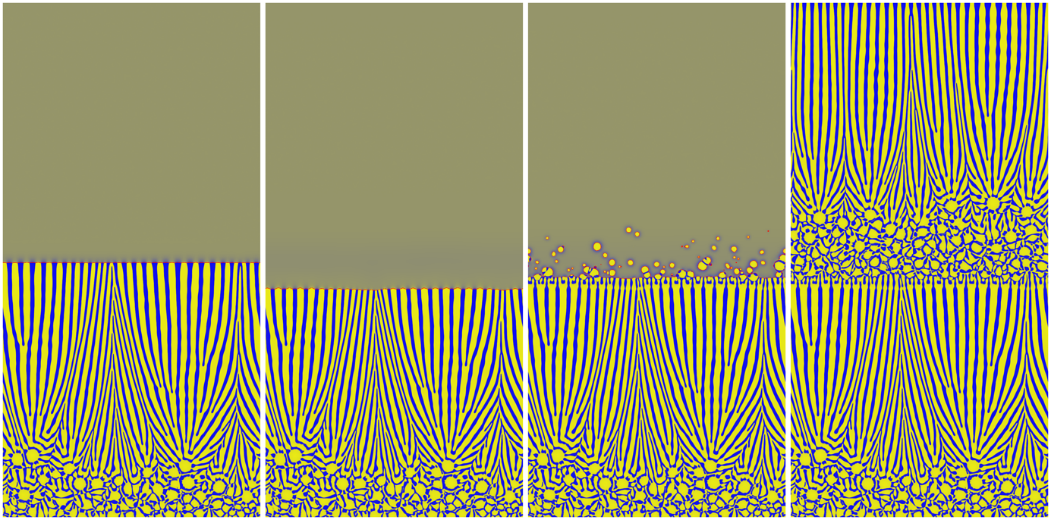

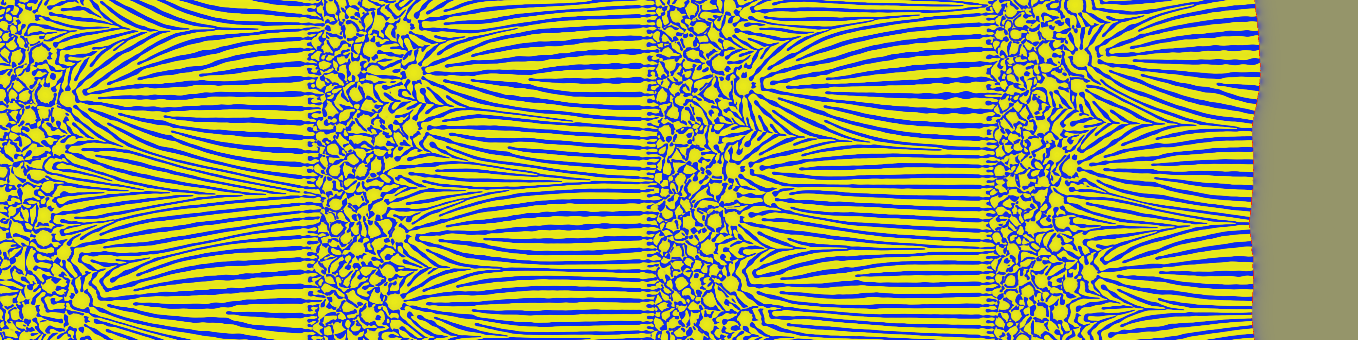

Computational Materials Science: In European collaboration, we investigated microstructure evolution during laser additive manufacturing (LAM) of hyperfine eutectic alloys in the Fe-Ti system, with the aim of designing materials for application in supercharger propeller (Bosch) and cloth cutting device (Procter and Gamble). Modelling of the microstructure was performed in the Wigner RCP using an orientation field-based phase field model, under heating and cooling conditions typical to LAM [4]. A layered structure consisting of alternating thin globular layers and extended lamellar domains was observed in the experiments. Its origin was explained in terms of a repeated remelting, nucleation, and growth sequence taking place after adding a new layer during LAM, as indicated in Figs. 1 and 2.

(a) (b) (c) (d)

Heating/Melting Cooling/Solidification

Fig. 1: Snapshots of the composition map from the phase-field simulation of melting and solidification during a full heating/cooling cycle of laser additive manufacturing. Time elapses left to the right showing (a) the lamellar eutectic structure from the previous cycle and freshly melted powder on the top, (b) the remelting the topmost part of the lamellar structure during heating, (c) the epitaxial growth of the lamellae and the nucleation of the primary phase ahead and (d) the subsequent growth of elongated eutectic grains during cooling. At this point, the simulation domain is stepped up by half the sample height and a new heating/cooling cycle can be started with a configuration similar to (a).

Fig. 2: Composition map of the layered microstructure seen in LAM-produced eutectic alloys as predicted by the phase-field theory.

X-ray related methods

Our research concentrated on the evaluation of Kossel patterns, which contain full crystallographic information on the sample, allowing unambiguous determination of the atomic structure. An autoindexing program was developed [5]. It allows the automatic indexing of the Kossel lines without preliminary knowledge of the crystal lattice. This work is essential for single pulse imaging experiments planed at XFEL-s, which will facilitate the measurement of various short lived phases at extremely non-ambient conditions.

References:

[1] Cadena, A; Botka, B; Székely, E; Kamarás, K. PHYS. STAT. SOL. (B) 257, 2000314-1-5. (2020)

[2] Gábor Bortel, Éva Kováts, Dávid Földes, Emma Jakab, Gábor Durkó, and Sándor Pekker, CRYSTAL GROWTH & DESIGN 20 : 6 pp. 4169-4175. , 7 p. (2020)

[3] Zhang, Y ; Yao, MG ; Du, MR ; Yao, Z ; Wang, Y ; Dong, JJ ; Yang, ZX ; Sundqvist, B ; Kovats, E ; Pekker, S et al., JOURNAL OF THE AMERICAN CHEMICAL SOCIETY 142 : 16 pp. 7584-7590. , 7 p. (2020)

[4] https://doi.org/10.1016/j.addma.2020.101133.

[5] https://doi.org/10.1107/S1600576720014892